Librem 5 Dogwood Update

Purism

Latest posts by Purism (see all)

- A Quarter Century After Cyberselfish, Big Tech Proves Borsook Right - December 20, 2025

- PureOS Crimson Development Report: November 2025 - December 15, 2025

- Purism Liberty Phone Exists vs. Delayed T1 Phone - December 10, 2025

Summary: We are almost at the end of the Dogwood board verification and have found and fixed a number of issues with the initial Dogwood boards. We believe we will be able to complete testing and start shipping Dogwood phones out within a few weeks. We have also been working on Evergreen in parallel to procure the remaining components we need for mass production.

We know the community is eager to hear any updates we might have about the Librem 5. Like with our Birch and Chestnut updates, we are trying our best to give you correct information for each batch with a reasonable level of confidence without venturing into speculation or guesses. This is especially important when it comes to reporting hardware updates as it can take time and iterations to trace down a problem into the component or mistake that caused it and often first guesses for a root cause prove to be incorrect.

Like everyone else we have been impacted by the COVID-19 pandemic and back in February we published an overall shipping update based on the best information we had at the time including dates for Dogwood:

- End of March: Librem 5 Dogwood internal hardware revision for the Purism team

- End of April: Librem 5 Dogwood batch for customer pre-orders

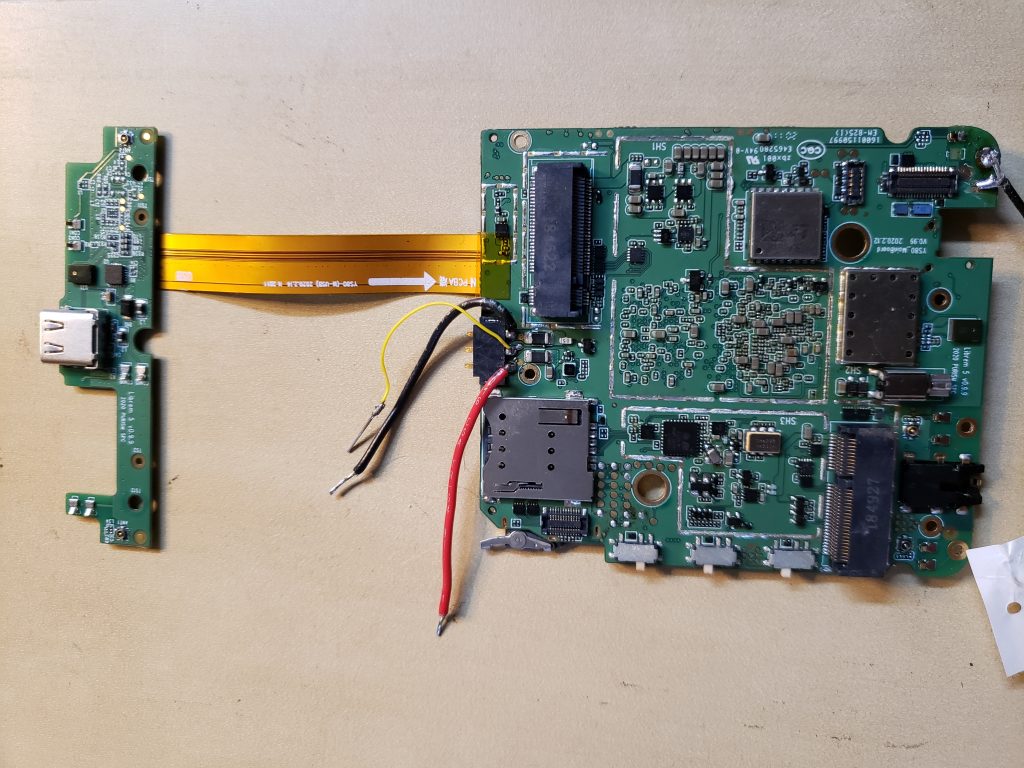

We started receiving the internal Dogwood hardware revision a bit later than expected in April and started the work to test and verify the changes. As we mentioned in our Breaking Ground post, the Librem 5 is an entirely new phone built from the ground up and that means significantly more testing and tweaking than with an off-the-shelf design. Unlike with Birch and Chestnut batches, which only had minor tweaks on the previous batch based on problems we uncovered during testing, Dogwood represented a much larger change–a CPU flip to the other side of the PCB to help with heat dissipation–that meant a full redesign of the PCB layout.

We knew it would take longer to test Dogwood compared to Birch and Chestnut and budgeted extra weeks for the tests assuming we didn’t come across any major issues. Once testing was complete we would apply any fixes and then send out the remaining Dogwood batch to customers. Like with Birch and Chestnut we wanted to bring you along for the ride and give you updates as we have them, but up until now there honestly hasn’t been all that much to report except that the testing was in progress. This kind of testing of every component in a long checklist is tedious work and is only interrupted with a bit of excitement when something doesn’t work as expected and you must drop everything to figure out why.

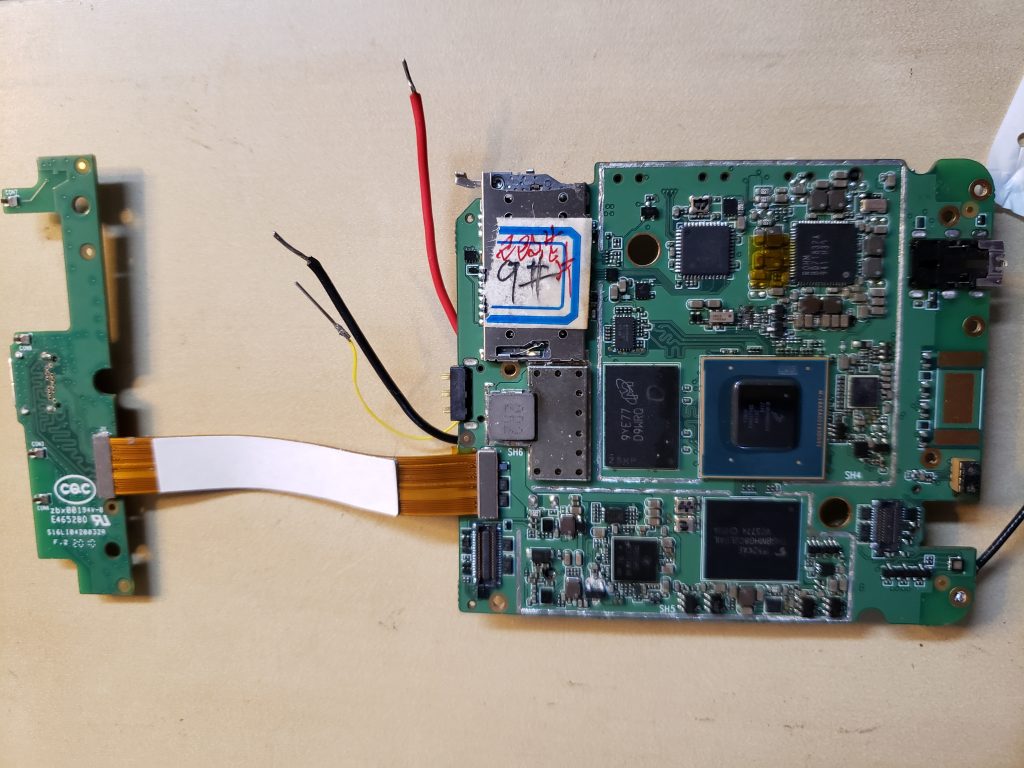

Dogwood Hardware Fixes

It’s been about a month since we started that verification and as expected we did find some issues with the initial Dogwood boards. Overall the glitches we found have been minor from a design and fix perspective such as an incorrect MOS FET transistor part and a minor mistake in the CPU power supply, but were glitches which resulted in odd and sometimes much larger problems in the functionality of the device ranging from damaging the USB section of the CPU in one case and disabling an entire I2C bus in another! It’s taken more time than expected to trace through these problems and then apply and test fixes especially in the case of the CPU since it required reworks in the PCB that were difficult to make on the existing boards and new CPUs.

Another system we have been looking into since Birch is GNSS (aka GPS). GNSS is a pretty delicate thing, the GNSS satellite signals are so weak, it’s like trying to spot an 80W light bulb in orbit (that’s about the energy equivalent). What is received on the ground here on earth is usually below the noise level of the antenna and takes pretty significant signal processing to get data from it. This means that the GNSS antenna signal path must be pretty close to perfect.

Besides this with Chestnut we discovered that ST Micro, the manufacturer of the TESEO LIV3 GNSS multi constellation receiver we are using in the L5, silently changed the recommendations for the antenna input electronics design. Now in Dogwood we see that GNSS reception still wasn’t great so we went back to suppliers and the drawing board, applied some more changes and are now finally getting a fix!

Of course, now is the time to apply all of these fixes, before we go into mass production. As you might expect, changes are much more complicated with larger volumes, which is why we chose the public small batch approach to begin with and invited you to come along with us for this ride. At this point we have successfully verified almost all of the components with only a handful left to go and we feel we are pretty close to being able to greenlight the remaining Dogwood PCB production within a week so we can start shipping a few weeks after that. While this has been going on we have also been working in parallel on Evergreen to complete procurement of the components we’ll need for mass production.

What’s Next

Now that we are almost to the end of Dogwood hardware verification, soon we will be able to shift focus from testing individual components on a PCB to evaluating Dogwood and the CPU flip in particular as a whole. We know many people are curious about the impact of the CPU flip on heat dissipation and we intend to publish more detailed analysis soon in a future update.

Recent Posts

Related Content

- PureOS Crimson Development Report: November 2025

- PureOS Crimson Development Report: October 2025

- Consent On Everything?

- 60 Minutes Uncovers Hacks on America’s Infrastructure

- Code is Power!